Overview

At SAC Corporation, we specialize in advanced external coating systems that enhance the life, strength, and performance of steel pipelines. Our coating solutions — 3-Layer Polyethylene (3LPE), Polypropylene (PP), and Fusion Bonded Epoxy (FBE) — are designed to deliver long-term corrosion protection even in the most demanding environments.

Key Features

· Superior corrosion and impact resistance

· Suitable for underground, underwater, and exposed pipelines

· Excellent adhesion, flexibility, and chemical resistance

· Ensures long-term pipeline integrity and minimal maintenance

· Compatible with seamless, ERW, LSAW, and Spiral pipes

Technical Details

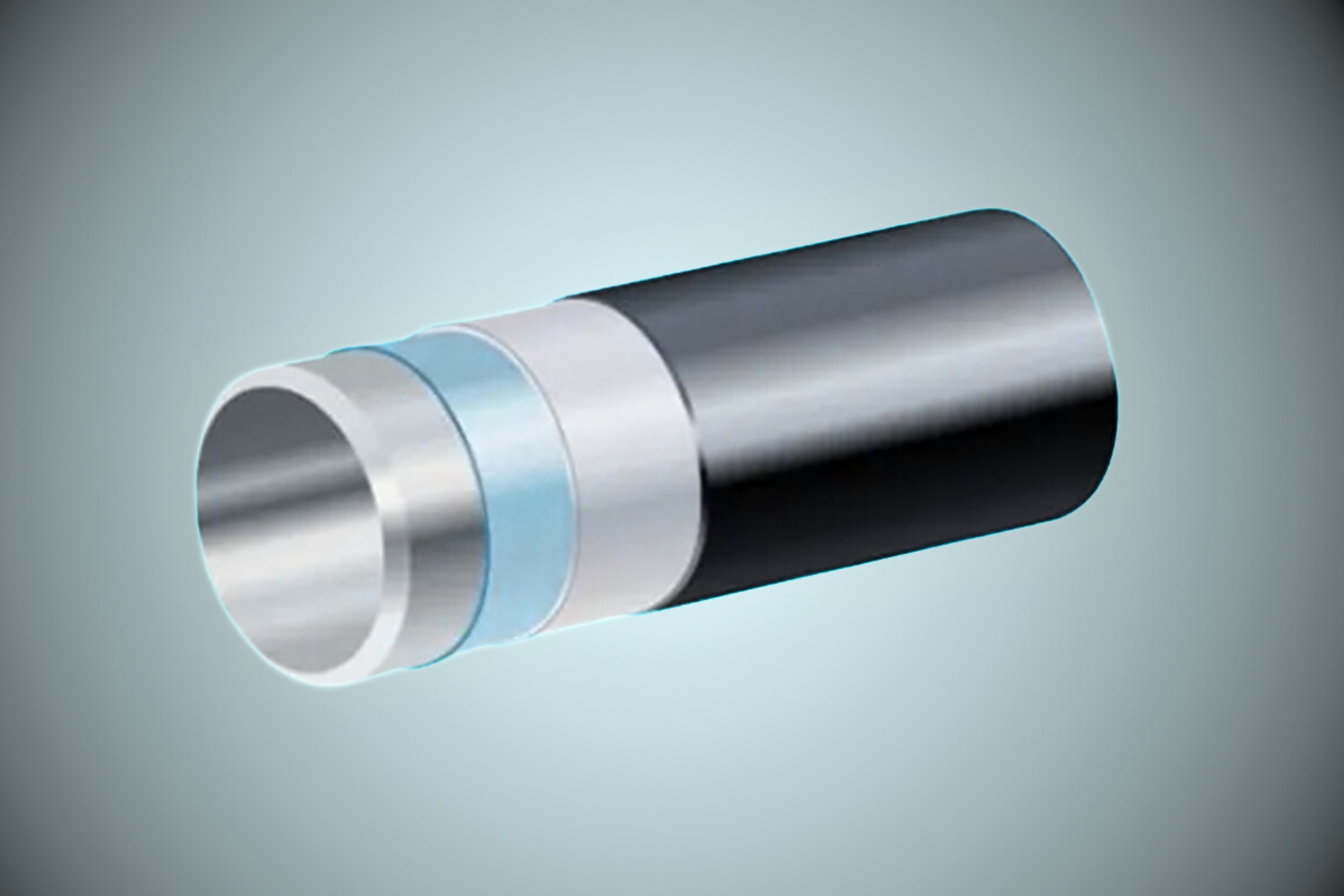

· 3LPE Coating: Combines FBE base layer, adhesive copolymer, and polyethylene outer layer for maximum protection

· PP Coating: Provides outstanding chemical and mechanical durability for high-temperature pipelines

· FBE Coating: A single-layer epoxy coating known for strong adhesion and resistance to cathodic disbandment

Applications

· Oil & Gas transmission pipelines

· Water supply and sewerage lines

· Industrial and marine pipelines

· Buried and submerged pipelines

Why Choose SAC Coatings?

· In-house coating facilities with NABL-approved testing

· Proven performance under stringent inspection standards

· Used in multiple government and infrastructure projects

· Backed by decades of material and coating expertise

Since 1942, SAC Corporation has been India’s trusted name in industrial steel, delivering durable and innovative solutions for industries and infrastructure.

Copyright © 2024 All Rights Reserved.